UEGCL employees at the World Day for safety and health at work 2023 celebrations

About UEGCL

Who We Are

UEGCL (Uganda Electricity Generation Company Limited) is a corporate body, incorporated under the Companies Act (Cap 110), the Laws of Uganda and in conformity with the Electricity Act, 1999. The company was incorporated in March 2001 to operate and maintain the formerly UEB’s Generation Stations at Nalubaale and Kiira Power Stations, and to complete the construction of Kiira Power Station.

UEGCL News & Blogs

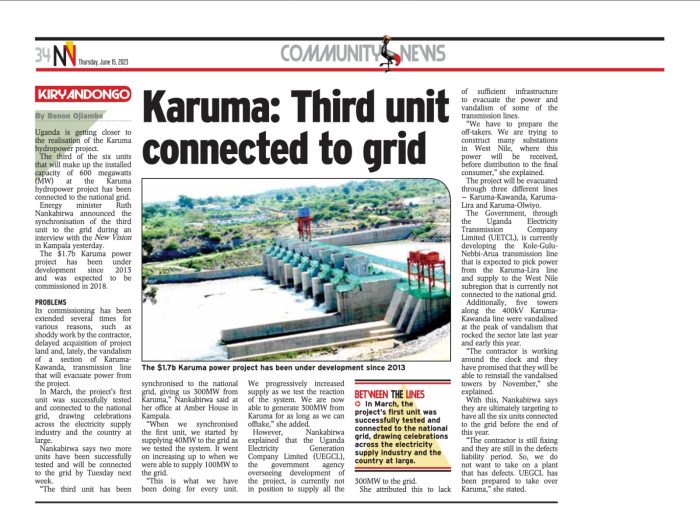

Major Hydro Powerplants

UEGCL offers expert professional services for all types of hydropower development projects from Mini to Large development schemes, low to high head projects, run of the river to storage schemes, surface to subsurface development projects etc.